Prior to beginning my career with Sun Plastech I worked for a high-speed injection molding facility. We averaged approx. 600 color changes per month along with 300 material changes. All the resins we used were olefins and we struggled daily with black specs and color streaking.

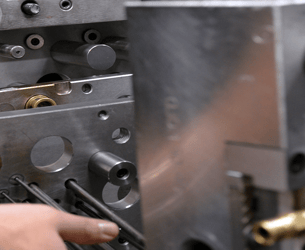

We used a purge compound to clean the injection molding barrels to make color changes more efficient, and to some extent it did. So we continued to use the purge, yet we still had issues with black specs and with colorant bleeding though. At times we pulled the screws, using torches and wire brushes to clean the carbonized resin. These machine overhauls were time-consuming, sometimes taking a full shift.

In retrospect we should have taken the time to educate ourselves on purging compounds, and learn that not all purge compounds are the same. We did not know there were purge compounds that remove degraded, carbonized resin. We did not know that sealing a machine properly during shutdown would prevent carbon from forming and facilitate quicker startups. We did not know that a purge compound COULD and SHOULD completely clean the machine. If we would have chosen the best purging compound for us, we would have saved thousands of dollars in overtime and hundreds of pounds of material over the course of a month.

Comments