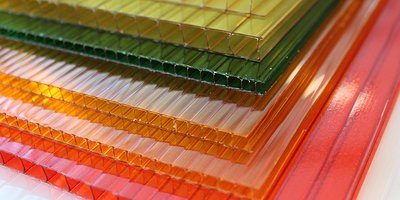

Chemical Purging Compounds are blended products that match your processing temperatures, your resins, your MFR’s, and your processing needs. Unlike Mechanical Purging Compounds, Chemical Purging Compounds clean using a heat-activated chemical reaction that performs best in low-flow and low-pressure environments. Chemical Grades are usually recommended for extrusion or blow molding because they expand to effectively clean large dies or other areas where contamination can hang-up.

Chemical Purging Compounds are strong cleaners that clean hard-to-reach areas within your machine. They do require a short soak time. Some people worry when they hear this but keep an open mind. If a Chemical Purge is cutting your changeover time in half, a short period spent cleaning the machine is more than worth it.

Let us help you find the best grade of Asaclean® for your processing goals. Request a Free Sample today and Learn why over 2,000 customers are currently using Asaclean®.