The best way to combat contamination is not to make it in the first place.

Using Asaclean® at regular intervals will keep contamination from beginning, and it typically only takes 1-3 barrels full of purging compounds to prevent or correct contamination. Most operations would much rather have a short, planned purging-related downtime event, than an unplanned screw pull.

It sounds simple because it is. If you follow these 4 steps, you’ll avoid unnecessary screw pulls and countless hours of tedious work and downtime.

Now that we’ve looked at ways to avoid most screw pulls, let’s take a quick look at some of the more common situations where screw pulls are necessary.

How to Optimize Planned Screw Pulls

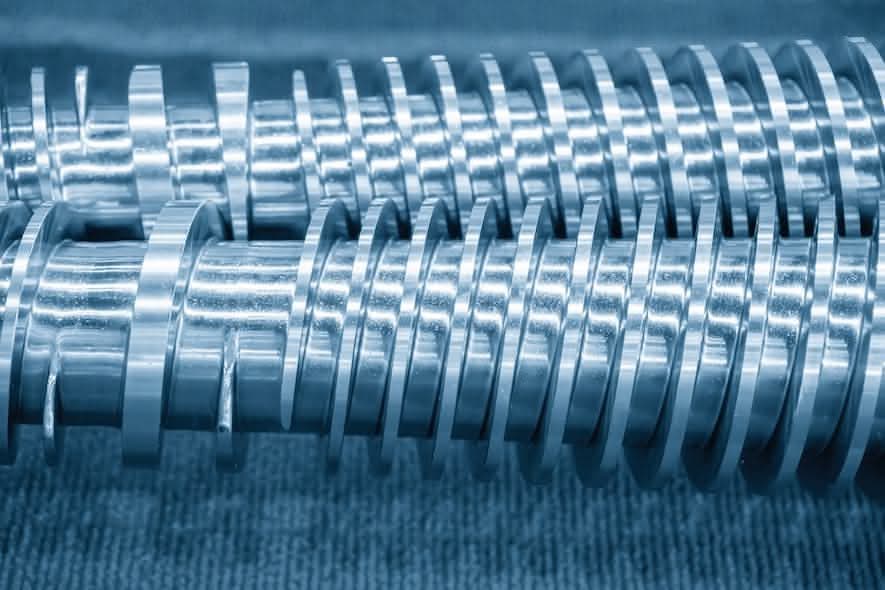

Most successful plastics companies pull/push screws as part of preventative maintenance. They do so not just to clean the screw, but also to get wear measurements on the screw and barrel. Extruders require screw pushes because they sometimes need different screw designs when running different kinds of materials. This is especially common amongst compounders. This kind of change cannot be avoided. We also see mandatory screw pulls in the medical and pharmaceutical markets, as well as in food packaging. Also, sometimes things just happen. Someone might forget to turn the heats off, or a shift might forget to purge between runs.

Just because these planned screw pulls are necessary, doesn’t mean they have to be a nightmare.