Cost Saving Solutions

Purging Compounds for Carbon Contamination & Black Specks

Every processor has dealt with carbon contamination and black specks. Gels, black spots, specks, and other contamination form when processing resins start to degrade within your machine. Once you notice defects in your parts, you need to address the issue immediately or your scrap will start piling up.

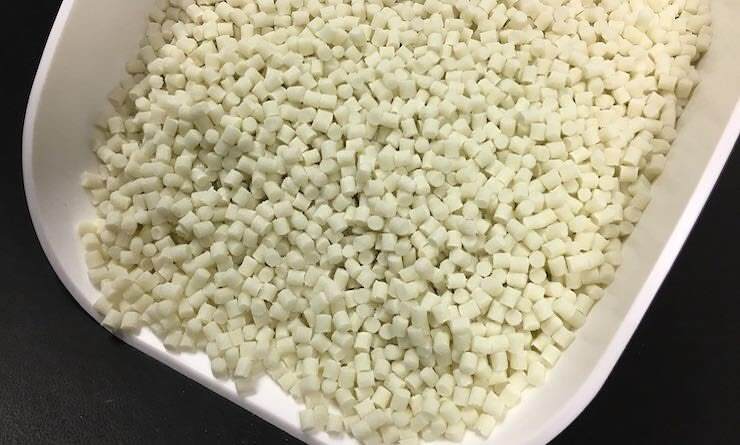

Whether you’re experiencing black specks at start-up or during your production run, Asaclean® helps you remove carbon contamination and get back to running good parts in no time.