Purging Compounds for Electronics

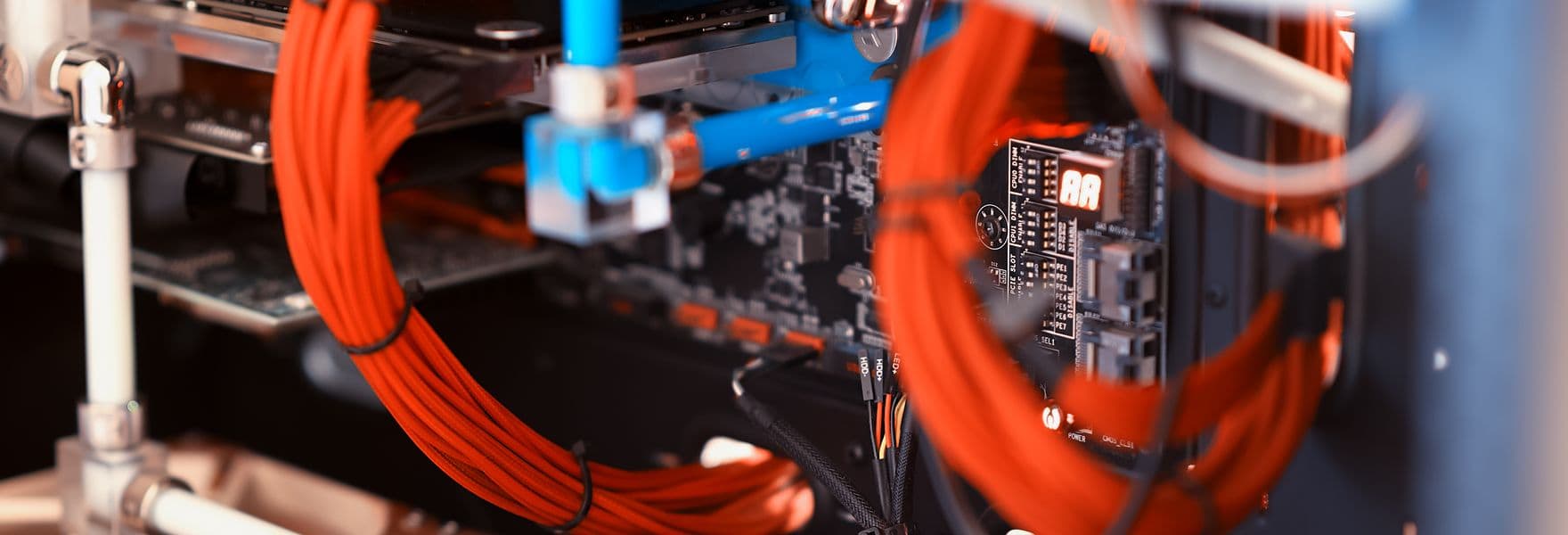

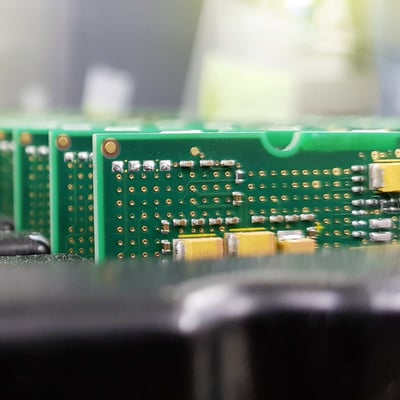

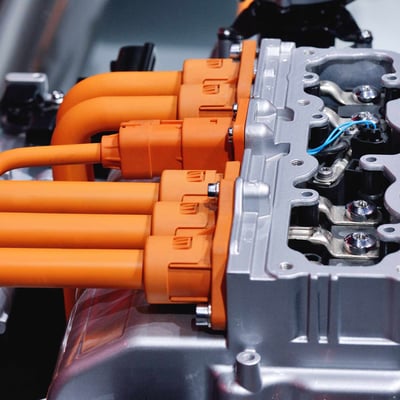

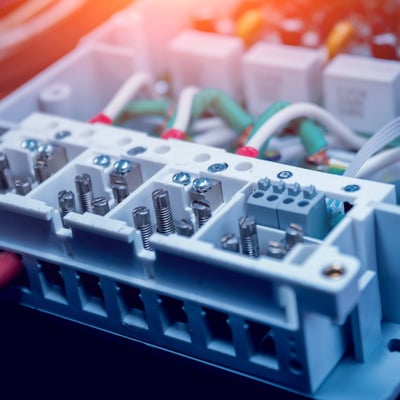

The electronics industry relies on almost every manufacturing process to deliver us the quality products we depend on every day. The industry is evolving, and customers need smaller and more complicated parts with a wide range of properties. Asaclean® has safe, effective, dependable, and affordable purging compounds designed for the specific needs of electronics manufacturers. Whether you’re coating wires, making connectors using hot runners, extruding battery separators in blown film, or molding phone cases, we’ve helped people just like you achieve dramatic cost savings.

Here’s why Asaclean® Purging Compounds are the preferred choice for the best electronics companies worldwide.