Purging Compounds for Injection Molding

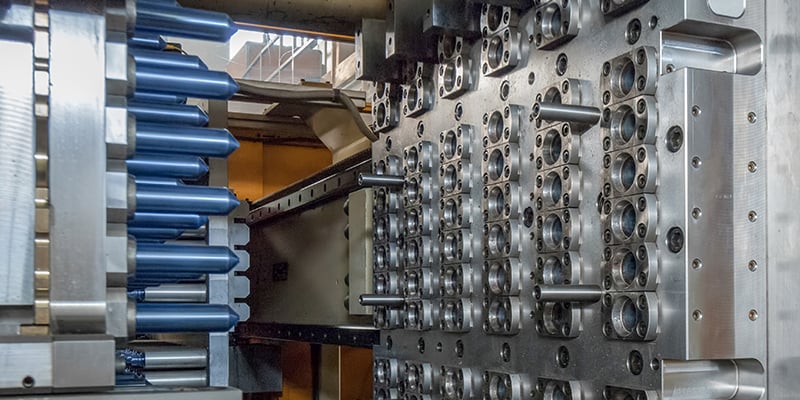

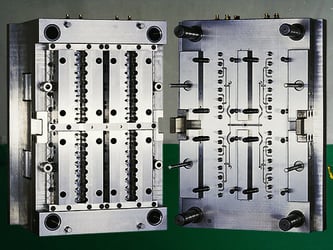

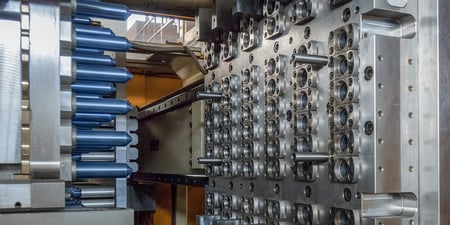

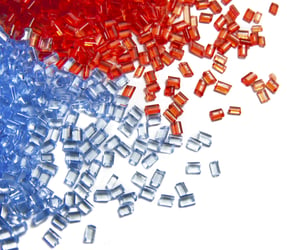

Every plant operates a little differently and there isn’t a one-size-fits-all purge that addresses every processing issue for injection molders. Whether you’re a custom molder with dozens of weekly color changes and material changes, a molder in caps & closures struggling with high-cavitation hot runners, or a medical molder focused on screw pulls, Asaclean® has a high-quality purging compound designed for your specific needs.

Here’s why Asaclean® Purging Compounds are the preferred choice for the best molding shops worldwide.