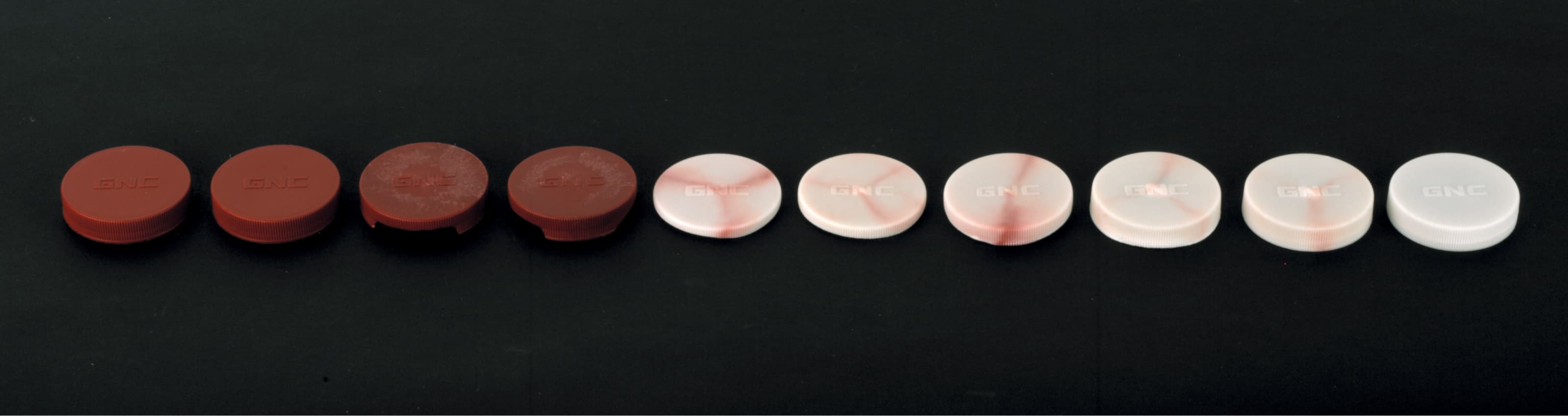

While color changeovers are a necessary part of the job, color contamination is not.

Color contamination is often a self-inflicted wound that occurs when a team runs from color to color without Asaclean® Purging Compounds.

We’ve all been there.

You’re on a tight deadline to get an overwhelming number of parts out the door.

You’re trying to save money and time.

You think you’re doing the right thing.

You switch to the next production resin and figure that it costs less per lb than your purge, and will get you to good parts eventually, so what’s the harm?

There are a few problems here:

1. Virgin or scrap resin (regrind) are not designed to clean out your machine.

Resin cannot effectively remove previous resins or color deposits from the previous run. Or worse, scrap resin can potentially re-introduce contaminants (color/carbon) into the machine. Purging compounds are formulated with detergency and cleaning power to both displace the previous resin/colors and clean the machine itself.

Although you will eventually see good parts using regrind or virgin, the previous resin is layering on your screw and barrel setting you up for serious contamination issues.