When customers come to us for help with material contamination, there are four common contributing factors:

1. Difficult Resins

Some resins are harder to remove than others. Every week we see the most changeover issues with PBT, PA, ABS, POM, PC, PVC, & PET.

Also, super-engineering resins can be a nightmare to cleanout. The cost-per-lb of these resins makes reducing scrap a top priority. Fortunately, a product like PX2 Grade makes these high-temperature changeovers painless.

2. Additives

Flame retardants, adhesives, carbon fiber, carbon black (used as an antistatic) and metallic conductive fibers all prove difficult to remove. They can burn easily or layer in the screw and barrel.

3. Pigments

Certain colors are more difficult to purge than others. We hear the most complaints about removing blue and red pigments. Additionally, running from colors into clear parts often takes significant time. If you’re making clear parts, anything left behind from the previous run will show up in your next parts. A clean screw and barrel are a necessity.

4. Processing Temperatures

Any scenario where you change temperature ranges increases the likelihood of carbon contamination and black specks. Low temp resins burn easily. Also, any situation where you step from super-engineering resins down to commodity resins is problematic.

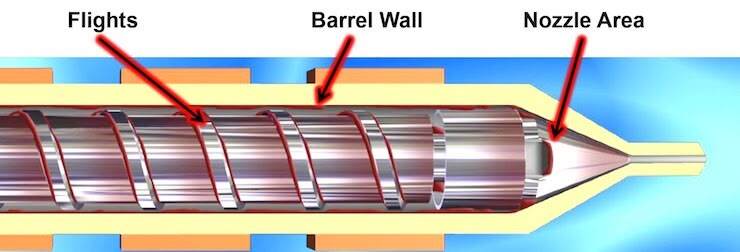

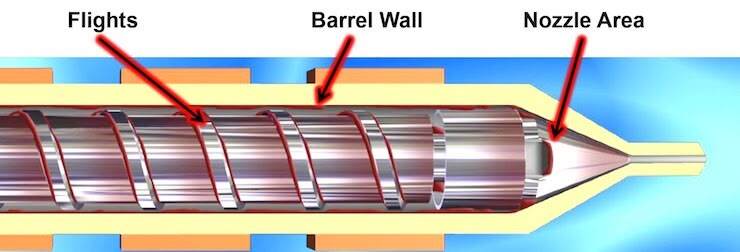

These factors lead to layering and are a ticking timebomb. Those layers will break off and end up contaminating other parts. Layers are most common on the flights, on the barrel wall, and in the nozzle area. Once layers form, contamination becomes more difficult to clean. Many maintenance teams rely on screw pulls and complete teardowns to solve the issue. You cannot afford extended downtime.

Whenever you change materials, it’s critical that you purge your machines to remove previously run materials and protect against contamination in your next batch. Although this is an additional step, the cost of including it in your purging procedures pales in comparison to the wasted materials caused by rejects. Our team of Asaclean® Purging Experts has seen it all. If you’re struggling with any of these issues, we’re here for you with a solution.