Purging for Packaging

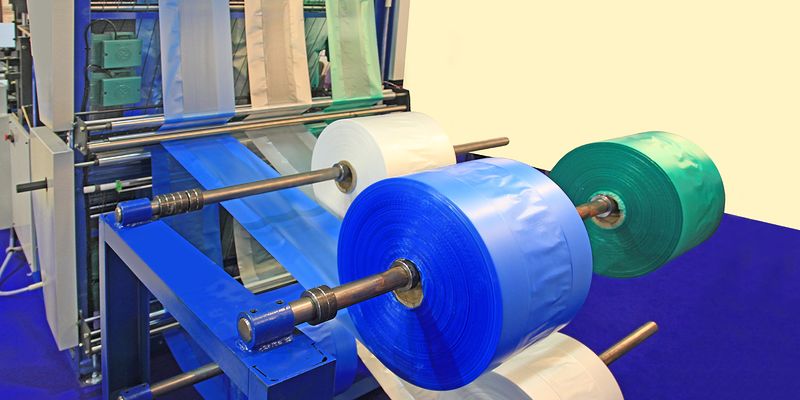

The packaging industry relies on almost every manufacturing process to deliver us the quality products we depend on every day. In your competitive market, sustainability, quality, & efficiency are essential to your long-term success. Asaclean® has safe, effective, dependable, and affordable purging compounds designed for the specific needs of packaging manufacturers. Whether you’re a sheet extruder making takeout containers, a molder making caps, a blow molder making detergent bottles, or a film extruder making saran wrap, we’ve helped people just like you achieve dramatic cost savings.

Here’s why Asaclean® Purging Compounds are the preferred choice for the best packaging companies worldwide.