Purging your extruder with the next resin or regrind is time-consuming, wasteful, and ineffective at removing color and carbon contamination. While you might think you’re running good product, a few things are happening that will cause much bigger headaches down the road.

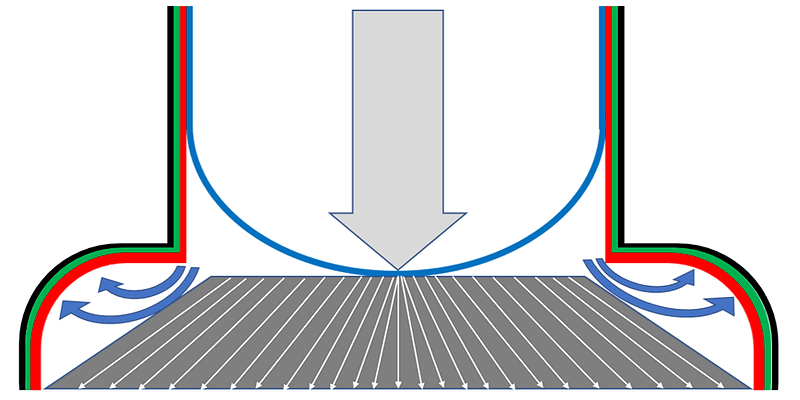

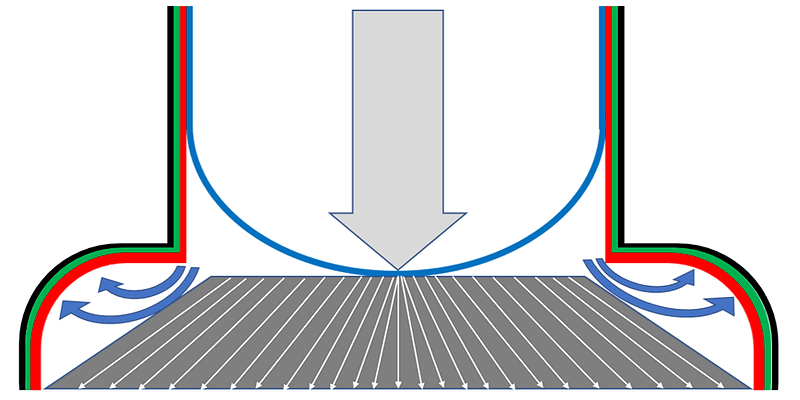

First, although you don’t see it happening, your resins are layering within your screw, barrel, and die. Eventually those layers will break off and cause contamination issues that will require a teardown.

Second, your output will decrease. Many processors call our team looking for answers about why their output dropped. Usually, this has to do with conditions changing within the screw and barrel.

Third, you are unnecessarily wasting time on changeovers, and production resins are too expensive to justify hundreds or thousands of pounds of scrap.

The cost of production resin isn’t so cheap anymore, and supply-chain issues make commodity and engineering resins much harder to come by. You can’t afford to waste production material. It’s scarce and costly.

Aside from regular and preventative purging, use a heat-stable purging compound like Asaclean NCR Grade for temporary or extended shutdowns and sealing, especially over weekends or holidays.

During a shutdown without purge, oxidation occurs which causes contamination, delaying startups and resulting in extended machine down. NCR creates an “air-tight” time and scrap environment in the barrel and promotes further cleaning during the shutdown.

4. If You Have to Push Screws, Use EX Grade to Reduce Downtime

Removing your screw from your machine without a purge requires great effort, and the cleaning itself takes hours of manual, tedious scrubbing. You must remove the layers of resins or contaminants that have accumulated around the screw. This excessive downtime is certainly affecting your company’s bottom line. If you’re running until failure or running until you experience severe contamination, EX Grade is a solution that can make your life much easier in a hurry.