In the challenging landscape of business longevity, the U.S. Bureau of Labor Statistics shows that only about 50% of new businesses survive beyond five years, and a mere one-third last over a decade. This reality underscores the importance of strategic investment in financial, human, and infrastructural capital, particularly in sectors like plastics manufacturing.

Investment: The Foundation of Business Longevity:

Financial capital is the initial fuel that propels a business forward. Human capital, often accounting for 50% of a company's value, is its driving force. Meanwhile, infrastructure forms the company's backbone. Distinguishing between mere expenses and actual investments is crucial in maintaining a healthy balance. Investments are expenditures that yield beneficial returns, ultimately contributing to the company's profitability.

Machine Maintenance: Essential for Operational Efficiency:

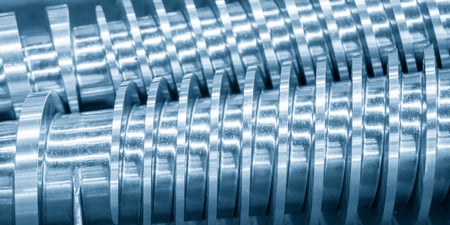

Machine maintenance is not just an operational task but a significant investment in the plastics industry. Proper maintenance ensures efficient processes, swift material changes, reduced downtime, and optimal production, all crucial for high-quality product output.

A Systemic Approach for Sustained Success:

Sustainability and success in the plastics industry require a systemic approach. This involves strategic investments that consider the interconnectivity of all operations, focusing on both short and long-term gains.

Reducing Costs with Effective Maintenance:

By investing in proper machine care, companies can save significantly on costs associated with extra workforce, quality inspections, and rework due to customer rejections.

The journey toward long-term success in the plastics industry is marked by strategic decisions and investments, especially in equipment maintenance and operational efficiency. Understanding and implementing these strategies is vital to surviving and thriving beyond the challenging early years of business.

Our role at Asaclean aligns with these objectives. We provide high-quality purging compounds for injection molding and extrusion machines, focusing on enhancing the longevity and performance of your equipment. While our products contribute to maintaining machine efficiency, the broader goal is to support your journey toward sustainable growth and operational excellence. In an industry where precision and quality are paramount, making informed choices about equipment care can significantly impact overall success.

In conclusion, the path to sustainability in the plastics industry is multifaceted, involving careful consideration of investments in technology, processes, and resources. By focusing on these critical areas, businesses can position themselves for a prosperous future, overcoming the hurdles that often challenge new enterprises.

Mario De León brings unparalleled experience as a Technical Sales Representative for Mexico, with a career in the plastics processing industry spanning every key position, from materialist to injection molding management. With more than two decades of experience, Mario has mastered the art of team leadership by sharing the acquired knowledge with love and a desire for growth. Recognized for building lasting relationships in the industry, his dedication to improving clients' operations and driving success demonstrates his invaluable contribution to our team and the plastics industry.

Comments