The cost of resins has been on the rise since last year, and some production facilities may be feeling the pinch now more than ever. When paying less than 50c/lb for some commodity resins, a few hundred pounds of resin waste may often have gone unnoticed in the past. In todays climate when you may be paying double for your resins, the costs associated with your resin waste will be doubling too.

To calculate how much your changeover is costing you, we consider the following:

- The machine running costs ($/hr)

- The time taken to complete a changeover (hours)

- Resin cost ($/lb)

- The amount of resin waste during the changeover (lbs)

When using a purge compound the aim is to reduce 2) and 4) which ultimately gives rise to a lower cost per changeover.

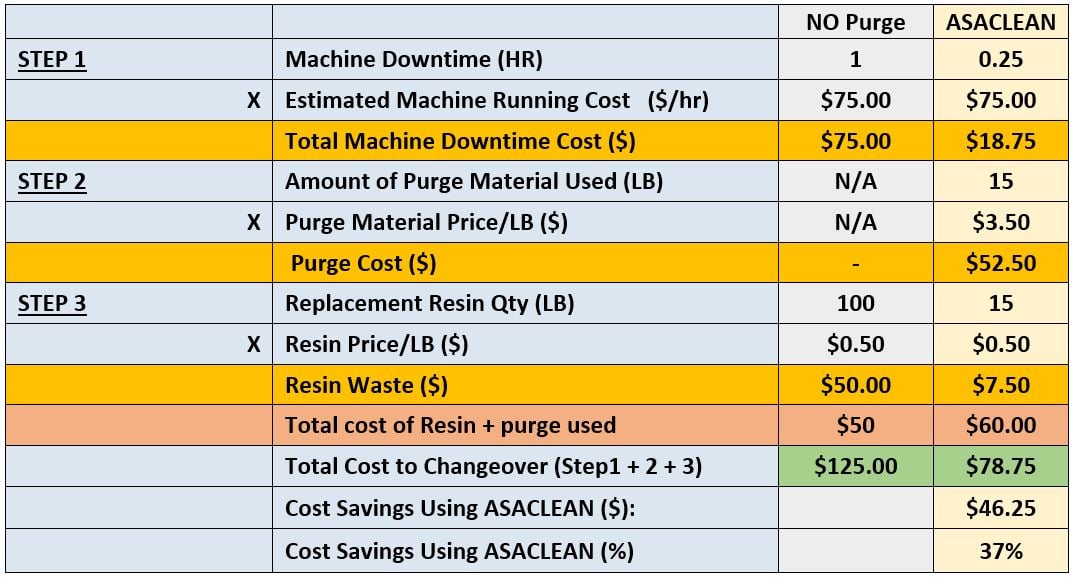

Historically, 1 hour of downtime and a hundred pounds of resin waste may have cost less to the processor, leading to the purge savings being small or negligible. Cost savings might be achieved by downtime but not necessarily in reduced waste. For example, see a real CSA that was completed for a small injection molder below:

Although use of a purge compound showed a 37% cost savings, the savings were coming entirely from downtime (not from reduced resin cost). In this case, the purchaser did not deem the savings in downtime alone as sufficient. As the total resin cost was less than cost of the purge, the company did not move forward.

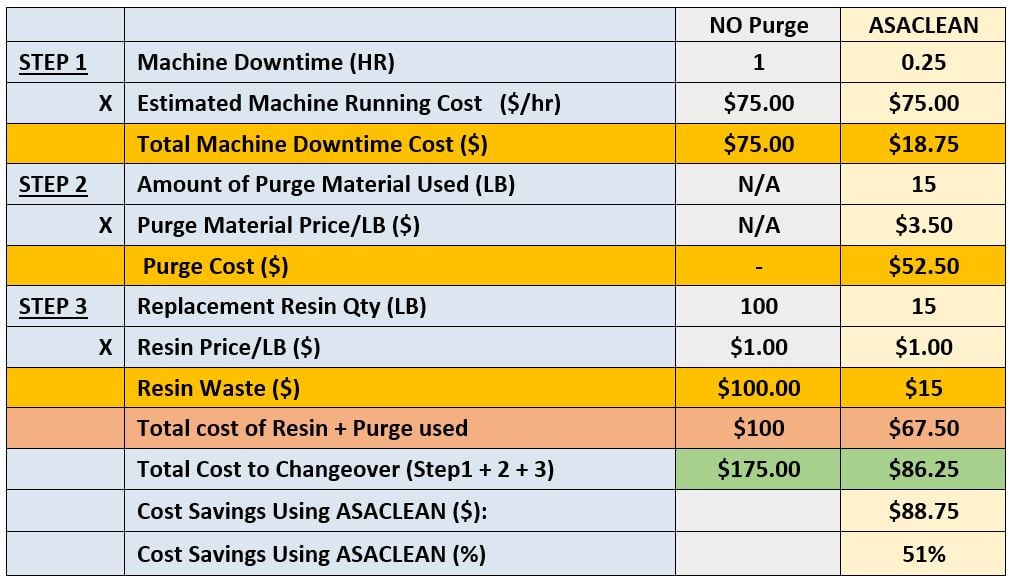

Later in the year when resin prices have almost doubled, the same cost savings analysis shows savings have increased by 15%. This time the cost of the purge and resin waste combined is LESS than total resin cost. Savings are coming from both machine downtime and reduced resin waste, making use of the purge much more economical.

In a time where resin prices are on the rise, using a purge compound to cut down on resin waste can multiply your savings more than before. Resin waste can no longer be ignored OR considered negligible and taking steps to reduce this waste will help increase productivity.

With more and more companies looking to achieve lean manufacturing, investing in a purge compound has become increasingly important. Cost Savings Analysis’ (CSA’s) show that purging will multiply your cost savings, by allowing you to complete your changeovers in less time AND by saving you from hundreds (or thousands) of pounds in resin waste.

Ready to reduce your production downtime to protect your profits? Learn more about how purging compounds and process efficiency work in tandem.

Kiran Raza is an Asaclean Purging Expert & Technical Sales Representative. She's worked in the plastics industry for nearly 20 years and has expertise In Bio-Medical Materials, Polymer Processing, and Materials Testing.

Comments